You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

needing a new MT clutch procedure

- Thread starter JayQQ97

- Start date

JayQQ97

MW surVivor ... clutched. 369k on the 0D0

its going to take time to properly vette these local places (i have 4 in cue) from prior experiences with various slop shops not doing job right the first time

the proper place for this procedure is likely outside of Chicago... but he has at least a 2 month backlog on maintenance on old rusty Toyotas

except when i last spoke with him regarding a new clutch he does not have equipment to resurface flywheel as needed and just recommends putting a brand new (very pricey part) one in there

the proper place for this procedure is likely outside of Chicago... but he has at least a 2 month backlog on maintenance on old rusty Toyotas

except when i last spoke with him regarding a new clutch he does not have equipment to resurface flywheel as needed and just recommends putting a brand new (very pricey part) one in there

Rock62

Well-Known Member

Replacement of such parts is common practice.

This comes due to the price and labor from a machine shop. Very few mechanics have the skills or equipment to surface a flywheel.

The work is usually done on a large grinder. Its not really an operation for a lathe.

Disc brake rotors have the same situation.

Remember, the longer you milk the worn out clutch the greater chance of severe damage to the flywheel. It may already be too late for a resurface. Prepare yourself for a significant repair invoice.

This comes due to the price and labor from a machine shop. Very few mechanics have the skills or equipment to surface a flywheel.

The work is usually done on a large grinder. Its not really an operation for a lathe.

Disc brake rotors have the same situation.

Remember, the longer you milk the worn out clutch the greater chance of severe damage to the flywheel. It may already be too late for a resurface. Prepare yourself for a significant repair invoice.

JayQQ97

MW surVivor ... clutched. 369k on the 0D0

Maybe 2 problems. Could be a throwout bearing, or related.

which problem are you referring to? I found the pressure plate has some sort of springs that could be an issue or not? with the floating sensation in the lower gears

apparently some shop will NOT resurface a flywheel

got an estimate from local indie yota shop that i THOT did resurfacing if it was resurfaceable

now they told me they just put a new flywheel in there

LOL

the deets on what EXACTLY they do with it dismantled in the 9 hours leaves much to be desired

Rock62

Well-Known Member

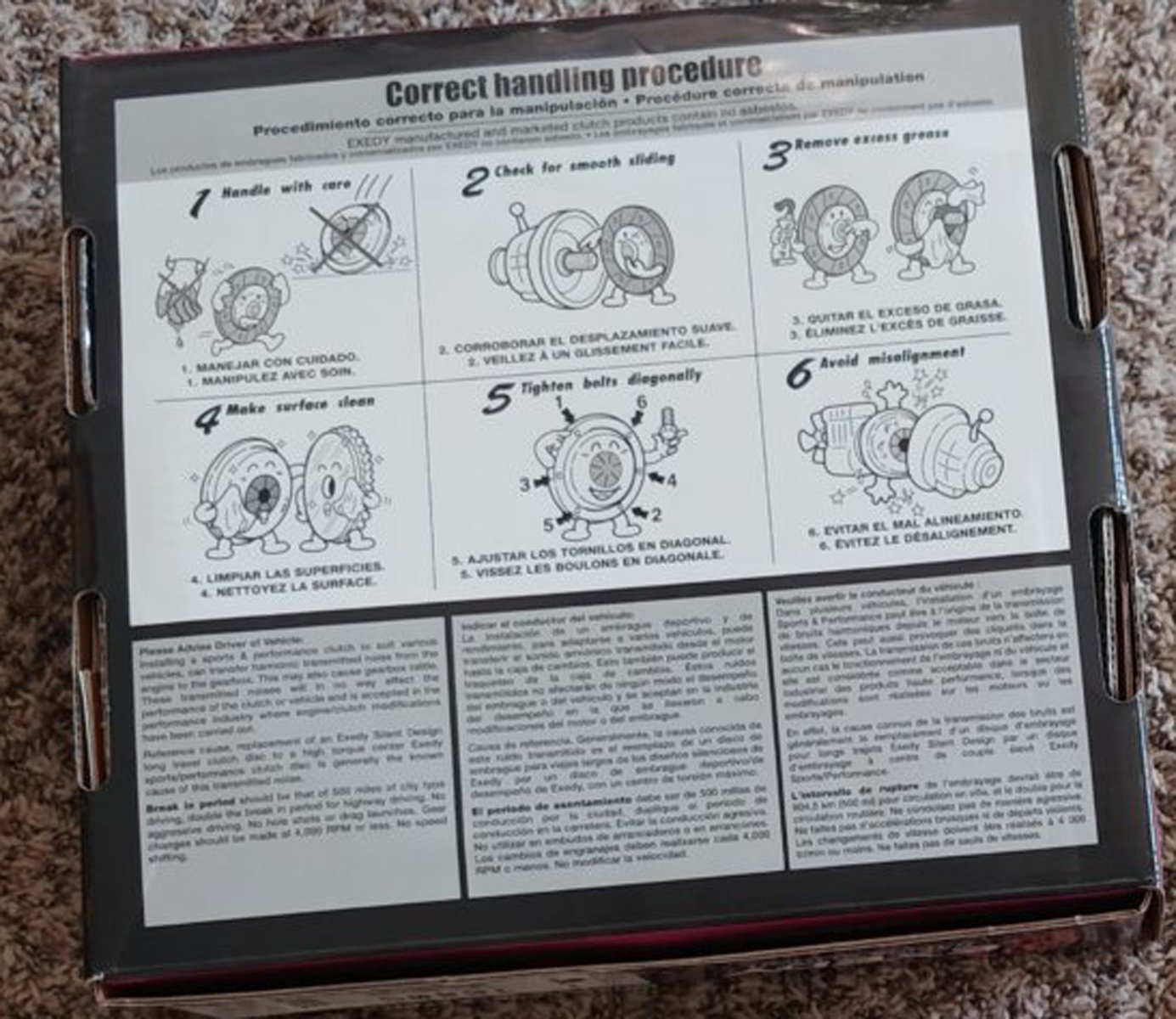

The pict-o-gram assembly is hilarious. The only mention of alignment is "Avoid Misalignment"........ not a clue on How to Align.

Suggest this not a typical DIY task.

Good Luck

BTW, you can always ASK the shop for the deets. If they are not willing to detail process, then find another shop.

Suggest this not a typical DIY task.

Good Luck

BTW, you can always ASK the shop for the deets. If they are not willing to detail process, then find another shop.

JayQQ97

MW surVivor ... clutched. 369k on the 0D0

this shop ONLY does Yota and LexusThe pict-o-gram assembly is hilarious. The only mention of alignment is "Avoid Misalignment"........ not a clue on How to Align.

Suggest this not a typical DIY task.

Good Luck

BTW, you can always ASK the shop for the deets. If they are not willing to detail process, then find another shop.

only other shop that does this local is the Yota dealer service shop

i asked if they inspect the transmission parts while its dismantled in case some things need replaced whilst its apart

and they said NO they will not look at transmission parts for wear

Rock62

Well-Known Member

Not surprised. Trannys are complex beasts. Yes, even the MT is complex.this shop ONLY does Yota and Lexus

only other shop that does this local is the Yota dealer service shop

i asked if they inspect the transmission parts while its dismantled in case some things need replaced whilst its apart

and they said NO they will not look at transmission parts for wear

From a shop view, it is time and $$ efficient to just put a rebuilt tranny in.

The issue you describe is likely limited to the flywheel, diaphragm spring, throw out bearing and clutch plate. But this is just a guess on my part. Best to have a shop check.

JayQQ97

MW surVivor ... clutched. 369k on the 0D0

They did ask me if it was slipping out of gear or revving high going nowhereNot surprised. Trannys are complex beasts. Yes, even the MT is complex.

From a shop view, it is time and $$ efficient to just put a rebuilt tranny in.

The issue you describe is likely limited to the flywheel, diaphragm spring, throw out bearing and clutch plate. But this is just a guess on my part. Best to have a shop check.

And I confidently said NO. Not yet

JayQQ97

MW surVivor ... clutched. 369k on the 0D0

i happened across this bit during research...

the certified transmission shop will test the mt clutch this way

wheels off the ground and parking brake set they will revv the engine in neutral and hold steady

then put it into 3rd gear and engage the clutch

the time it takes for the engine to stall will indicate how much the clutch is actually worn

the certified transmission shop will test the mt clutch this way

wheels off the ground and parking brake set they will revv the engine in neutral and hold steady

then put it into 3rd gear and engage the clutch

the time it takes for the engine to stall will indicate how much the clutch is actually worn

When I worked in the Ingersoll rand machine room, I used one of their blanchard grinders to do a flywheel on a 84 Toyota pickup 4wd manual.Replacement of such parts is common practice.

This comes due to the price and labor from a machine shop. Very few mechanics have the skills or equipment to surface a flywheel.

The work is usually done on a large grinder. Its not really an operation for a lathe.

Disc brake rotors have the same situation.

Remember, the longer you milk the worn out clutch the greater chance of severe damage to the flywheel. It may already be too late for a resurface. Prepare yourself for a significant repair invoice.

JayQQ97

MW surVivor ... clutched. 369k on the 0D0

10-March-2o23

there is no difficulty getting into gear

there is no difficulty getting out of gear, even in reverse

there is no slipping out of gear

there is no slipping RPMs going up whilst steadily climbing a large hill in the top 5th gear

there is no grinding of gears when changing gears, when it does happen on occasion (not frequently!) it is accounted to user error

there is no difficulty getting into gear

there is no difficulty getting out of gear, even in reverse

there is no slipping out of gear

there is no slipping RPMs going up whilst steadily climbing a large hill in the top 5th gear

there is no grinding of gears when changing gears, when it does happen on occasion (not frequently!) it is accounted to user error

Last edited:

Rock62

Well-Known Member

Ahhhhh...... a little "government" work.When I worked in the Ingersoll rand machine room, I used one of their blanchard grinders to do a flywheel on a 84 Toyota pickup 4wd manual.

A Blanchard is a fairly large grinder. I worked for Gardner-Denver once upon a lifetime ago. We had some big grinders to surface the discharge plate of the screw compressors.

I remember doing competitive testing on a few IR compressors.

JayQQ97

MW surVivor ... clutched. 369k on the 0D0

so i finally found a suitable transmission place to drop off early Monday for some test driving and whatnots to find the issue

there was no mention of a 'diagnostic fee' which i have every right to balk at from prior multi-experiences with that BS scheme

more happy trails to all!

there was no mention of a 'diagnostic fee' which i have every right to balk at from prior multi-experiences with that BS scheme

more happy trails to all!