JayQQ97

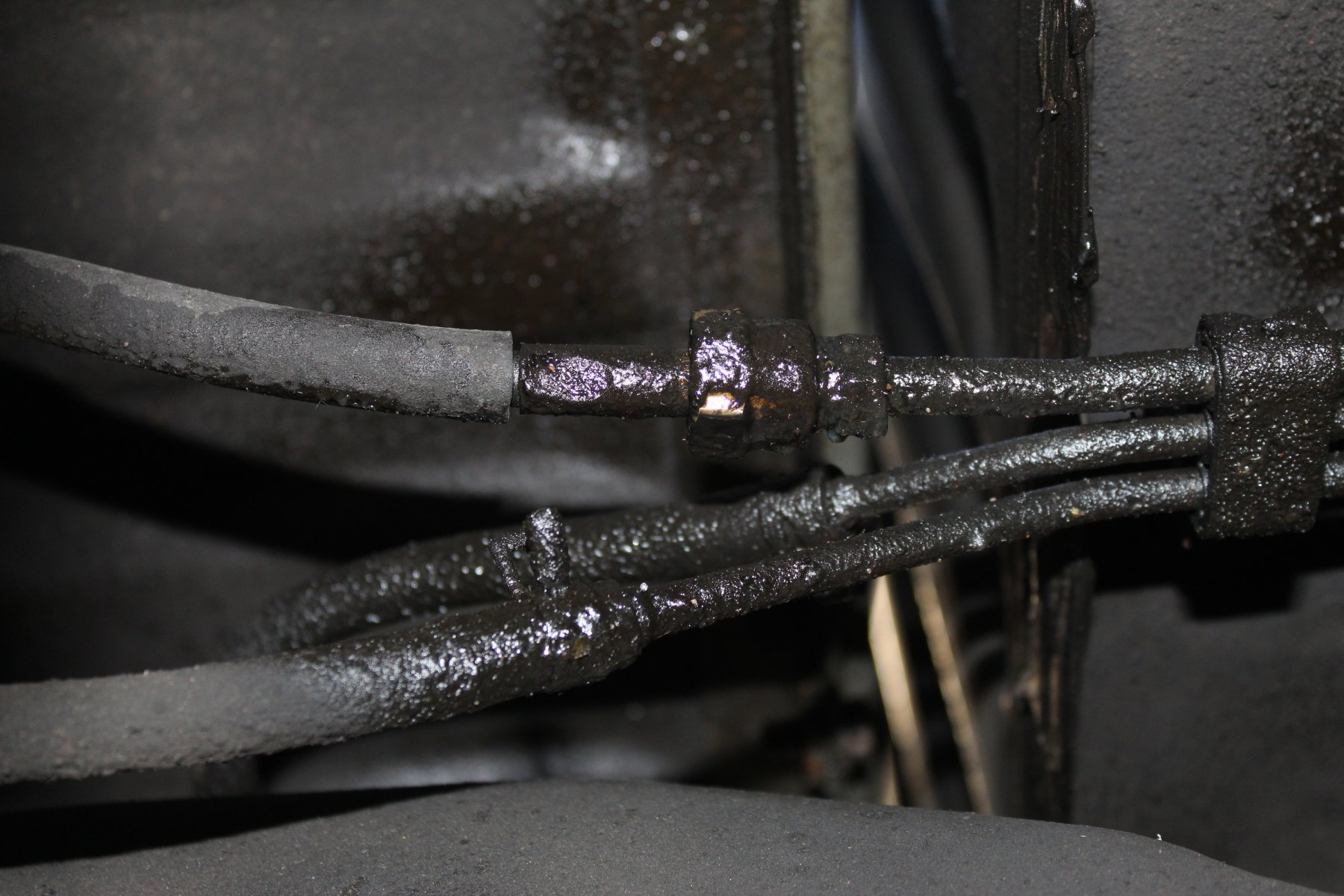

MW surVivor ... clutched. 350k on the 0D0

this is the best video i have found so far for attempting this

although it's for a gen3 T4R circa '97 and not a taco

unfortunately, there are quite a few differences between the two

shooting for May or perhaps June for this belaboured task

although it's for a gen3 T4R circa '97 and not a taco

unfortunately, there are quite a few differences between the two

shooting for May or perhaps June for this belaboured task

Last edited: